To lower costs and improve productivity printing presses do not print a single page or artwork at the time. In one single go a press may print 4, 16 or even 96 pages. Imposition refers the prepress process of positioning pages or artwork on press sheets in such a manner that the job can be printed and finished properly and efficiently. It is a fundamental step in preparing a job for print and it requires a lot of insight in the way the entire production process works. That means imposition is also handled differently for commercial, newspaper and packaging jobs.

What is common for all three types of work is that the imposition work is not limited to positioning pages or artwork on a sheet. Part of the process is making sure that all the marks that are needed by the printing presses and finishing machines are added. This includes cutting marks, color bars and collation marks. All these production-related graphic elements are called the furniture.

Imposition for commercial jobs

Commercial printing includes producing catalogs, magazines, brochures, leaflets, flyers, stationery, business cards as well as posters and billboards.

Imposing signatures

For multipage documents such as magazines or brochures, all the pages are combined in signatures, which are printed sheets that are folded to the required page size.

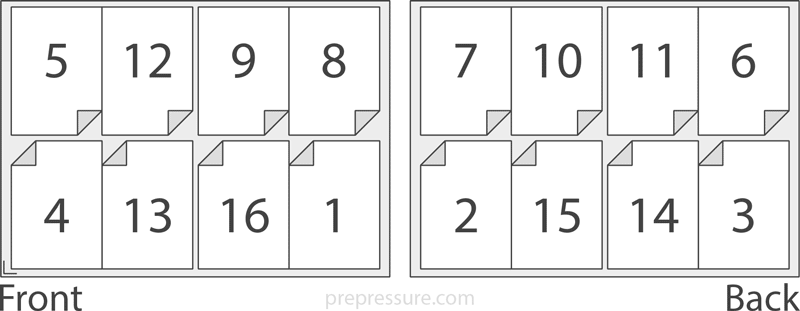

The example below shows an imposition scheme that can be used for imposing 8 A4 pages on an SRA1 sized sheet.

Signatures contain multiple pages. An imposition scheme determines how those pages will be positioned on the signature. How many pages are combined, how these are positioned and which additional information is added to the signature is determined by many parameters:

1. Page and sheet size

On a press capable of printing on SRA1-sized sheets, which measure 640×900 mm, you can put 8 A4-size pages. The ability to print 8 A4 or Letter size pages in one go is called an 8-up. There are 2-up, 4-up, 8 up,… devices.

2. The number of pages of the printed product

The compositor must determine how many sheets are to be printed to create a finished book. Some products, such as digitally printed

3. Job content

It doesn’t happen very often but sometimes the content of pages, such as large flat tints or dark images, require a change in the imposition template to make the job easier to print.

4. Printing press

The choice of printing press has a major impact on the imposition process. It affects both the work style and the position of the pages on the sheet.

The work style

The work style deals with the way the press sheets will be printed.- If both the front and back of the sheets need to be printed, you can make one set of plates for printing the front and one set of plates for printing the back. There are two ways to handle this:

– If both the front and back of the sheets need to be printed, you can make one set of plates for printing the front and one set of plates for printing the back. There are two ways to handle this:- Sheetwise

– Sheetwise

The printer first prints the front, then removes the first set of printing plates from the press, mounts the plates for the back and sends all the press sheets through the press a second time to print the back.

– Perfector

Perfector is a variation on sheetwise. A perfecting press prints both sides of the paper in one go. You still need separate printing plates for the front and back but after the front has been printed, the press flips over the press sheet and prints the back.- Instead of making separate plates for the front and back, you can also combine both sides on just one set of plates. The first time the press sheets are fed into the press, half of the pages that are printed

– Instead of making separate plates for the front and back, you can also combine both sides on just one set of plates. The first time the press sheets are fed into the press, half of the pages that are printed qre front pages, the other half are back pages. Then you flip the paper stack over and feed the pages through the press a second time. Once printed, the sheets are cut in half before folding, creating two identical copies. Depending on how you rotate the stack of press sheets, the work style has a different name:

– Work and turn

The axis runs perpendicular to the grip of the sheet.

– Work and tumble

The axis runs parallel to the grip of the sheet.

– There are also a couple of special cases.

– Come and go

To be documented

– Cut and stack

After all the pages have been printed they are stacked and then cut. There is no folding. Take for example a single copy single sided 100-page job that gets printed on a 4-up press: page 1 is on the top left of sheet 1, page 2 is on the top left of sheet 2,… down to sheet 25. Page 26 is on the top right of sheet 1, page 27 is on the top right of sheet 2, and on down the stack. A stack of 25 sheets is printed and cut so that you have a stack of pages 1-25, another stack of pages 26-50, a third stack of pages 51-75, and a fourth stack of pages 76-100. All that now needs to be done is putting the stacks in the proper order. Cut and stack is often used on digital presses. It is used for a variety of documents, including things like numbered tickets.

– n-up imposition

This is the simplest imposition method: pages are simply imposed in the order in which they appear in the original file. Even office applications like PowerPoint offer this type of imposition to output multiple slides on a single page.Sometimes binding styles are combined within a single job. This is called mixed binding.

Sometimes binding styles are combined within a single job. This is called mixed binding.

The position of the pages on the sheet

Sheetfed presses have a grip: their clamps grab the paper to feed the press sheet through the press. That influences the distance from the bottom of the press sheet to the start of the first page.

Press marks

The control system of the press also dictates if registration marks, a colorbar and other elements need to be added to the sheet.

5. The binding style

Many publications contain so many pages that they are printed using multiple signatures. When there is no binding involved, such as with posters, inserts, business cards, or leaflets, this is usually called flat work.

When a job requires multiple signatures, then how these signatures are bound also affects the imposition scheme. The two main binding styles are:

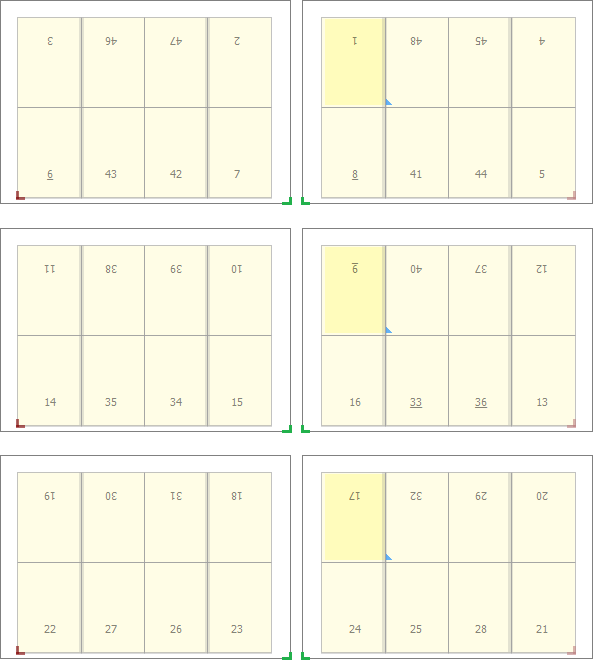

– Saddle stitched binding

All the sheets are printed and folded, after which they are inserted inside each other and one or more staples are applied to the spine. This means the first sheet contains both the first and the last page of the publication. The example below shows the front and back of the three signatures of an 48 page saddle stitched job imposed for an 8-up press.

– Perfect bound

All the sheets are printed and folded, after which the folded sheets are stacked on top of each other. Glue is applied to the spine and a cover sheet is wrapped around the book to encase the spine. The means the first signature contains all the pages from the first part of the publication. The last pages are on another sheet. The example below shows the front and back of the three signatures of an 48 page perfect bound job imposed for an 8-up press.

In some cases the imposition has to address physical properties of folding sheets, such as creep, bottling and web growth. In general, the bigger the signatures or press, the more these effects come into play.

– Creep is also known as binder’s creep, pushout or thrust. It refers to the gradual extension of the inner signatures of a saddle-stitched job beyond the edges of the signatures that surround them. After cutting this means the inner signatures are less wide than the outer ones. To compensate for this effect, the content of the pages of the inner signatures is shifted slightly. This is called shingling.

– One effect of folding a signature is that the pages might bottle: they get rotated or skewed a bit. This is mainly an issue with very large signatures that get folded a lot. To compensate for this effect the pages are counter-rotated a tiny bit in the imposition program.

– While paper travels through the press, it can get stretched or deformed. This effect is called web growth and it occurs mainly with large thin or lower quality rolls or sheets of paper. The deformation can happen across colors (on the magenta cylinder, the paper is wider than on the black cylinder) or it can even happen within one single separation (the leading edge of the sheet is slightly smaller than the trailing edge). On web presses paper stretches across the web. On sheetfed presses the deformation is mainly in the direction of paper travel. The deformation can be linear, non-linear, trapezoidal or pillow-shaped. High-end imposition software can compensate for web growth.

6. Binding equipment

To be documented

7. Cutting equipment

To be documented

8. Paper grain

The fibers in many paper types are aligned in a specific direction. When pages are folded, this is best done parallel to the paper grain. That means the direction in which pages are oriented on a press sheet is partly determined by this grain. This does not mean all the pages are oriented in the same direction. Pages are frequently positioned head-to-head.

Sometimes the paper grain is irrelevant or not an issue (e.g. when printing cards) which means a sheet can be filled with pages that do not all have the same orientation. That is called a dutch cut.

Step-and-repeat & ganging

When a single job is repeated multiple times on a press sheet, as is often the case with small documents, that is called a step-and-repeat job. When multiple jobs are combined on a single press sheet, that is called ganging. A typical example is filling a press sheet with business cards.

Imposition software

Imposition used to be a manual process but nowadays it is handled by software.

- There is dedicated stand-alone imposition software such as Kodak Preps, Dynagram Dynastrip or Ultimate Technographics Impostrip.

- In some workflow solutions such as Agfa Apogee Prepress there is a dedicated module, Apogee Impose, to take care of imposition pages.

- There are plugins for applications like Acrobat. Quite Imposing is a popular one.

- Some people impose pages in a layout application, for example by creating a large page in Adobe InDesign into which they import PDF pages which are then manually positioned correctly.

Imposition for newspaper jobs

Imposing newspaper pages is less demanding than imposing commercial printing jobs. Newspaper web presses are large but the plates are usually small and multiple plates are mounted on each cilinder. These newspaper plates contain either one or two newspaper pages. When two pages are combined on a single plate, that is called page pairing.

In CtP systems loading and unloading plates takes time, so that are some newspapers that use large plates, image multiple pages on a single plate and then cut up the printing plate to create smaller newsletter plates. This obviously means that the imposition template needs to be adapted and registration marks need to be added for the automated cutting system.

Imposition for packaging jobs

In packaging a single artwork or variations on the same artwork are typically repeated multiple times. Since boxes usually have an irregular shape, the artwork may need to be interlocked to minimize waste. That is called nesting. When the nesting is done based on the actual die cutting data, it is called true shape nesting.

Other sources of information

Wikipedia has an article on imposition.

I need more insight into come and go templates, I notice you set it to more documentation needed kinda thing…can you explain what it is and when to use it?

PDF Snake was the best-selling Adobe Acrobat plug-in for imposition in the early 2000s. It has been reborn as a web application. It’s easy to use, free to try, and very inexpensive.

https://pdfsnake.app

Hi there!

if any body want standalone imposition software you can get from this link.

https://www.youtube.com/watch?v=vAd9KkBlsiM&t=238s