Apogee Prepress from Agfa is an example of a modern prepress workflow solution. Below is an overview of:

- the system architecture

- the main workflow components or task processors

- types of jobs

- production management functions

Other prepress workflow systems like Kodak Prinergy, Heidelberg Prinect of Fujifilm XMF may use a different terminology or structure but they share many characteristics with Apogee.

System overview

- The Apogee Prepress software runs on the Microsoft Windows platform. It is a scalable system, which means that it can make use of a single computer but, if more horse power is needed, some of its modules can run on separate systems. These additional PCs are called satellites.

- Apogee Prepress is a client-server architecture. There is a separate dedicated application to manage Apogee, as well as an option to do basic job management from a web browser. This means operators usually don’t work directly on the main server but use a separate computer to manage Apogee. They can do this on-site or remotely, which is handy at printing companies that have multiple production sites but centralized their prepress operations in a single plant.

- Apogee is database driven. There is a central database that is used to keeps track of all the jobs, locations of files, system settings, etc. The type of database used depends on the workload and job volume.

- The system supports virtualization, meaning that the software does not run directly on the hardware of a computer but instead runs on VMware virtual machines. This is mainly done at large production sites because it makes it easier to scale the system and guarantee up-time in case of hardware issues or data corruption.

- Apogee can run on-site or it can be used in a cloud-based subscription model, called Apogee Cloud

- To extend the scope of the system, Agfa offers an additional suite of applications to integrate ecommerce (Apogee StoreFront), remote approval (Apogee WebApproval), cloud-based data exchange (PrintSphere), etc

Components

Most prepress workflow systems in the market are modular: you can buy a base system and expand it. The same is true for Apogee Prepress, for which various versions are available. Optional modules, called task processors, allow you to expand the system. Here are some of the main task processors:

The Hot Folder task processor is used to send data to a job. It allows you to define that a certain folder on the server or elsewhere should be checked regularly for data. As soon as PDF files, PostScript data, TIFF files,… are dropped in that folder, they get picked up and made a part of the job. There are a number of other input devices as well. Two of the more interesting ones are the Apogee Portal input channel, which enables customer to upload data using a web site, and a JDF/JMF input channel for automatic job and data submission using the JDF protocol.

The Preflight task processor uses PitStop to check incoming PDF files. Next to checking the resolution of images, the presence of fonts and dozens of other settings, the module can also be used to fix certain issues. Check the page with preflight recommendations for more details on the way a system should be set up. Since it runs in the background, preflighting every single incoming file doesn’t take up any operator time.

The Run List task processor is used to put all incoming pages into the correct order. This can be done automatically, provided the designer or agency used a logic set of file names. Unfortunately that is seldom the case. Since PDF is the internal file format within Apogee Prepress, pages in the Run List task processor typically are PDF files. Doubleclick ’em and they open in Acrobat – which is really nice!

One of the most important modules is the Impose task processor. As its name implies, this takes care of imposition, based on templates coming from Preps (my choice) or one of the other supported imposition applications. The ability to preview all imposed flats before sending them to the platesetter is very practical. Since Apogee has its own imposition engine, it can also handle JDF jobs that including stripping data. That is however only used in fairly rigid workflows where automation is easier to achieve.

The RIP inside Apogee Prepress is called PDFRender. It is based on the Adobe PDF Print Engine. The older Adobe CPSI RIP is still available for job reruns, when consistency with an old print job is crucial. You can purchase multiple renderers and have the system load balance all signatures or pages across these RIPs. It is pretty impressive and fast when you see 3 or more RIPs crunch big jobs. I’ve readied jobs in an hour or two that used to take a full week just a few years ago.

Apogee can drive multiple output devices. These can be physical devices such as an imposition proofer or a CtP device. It can also be logical or file devices, such as PDF output device or a virtual imagesetter that generates TIFF 1-bit data. Obviously you can use multiple devices in a single job because you need both proofs and plates. It is this type of automation where the difference with a ‘Do it yourself’ workflow can be pretty big.

Of course Apogee Prepress can drive a number of digital presses, predominantly Agfa inkjet systems. In an offset environment, presses such as the Generic Press are used to define processing settings. These can include dot gain, the target color space or the type of CIP3 file with ink key settings that needs to be generated.

Creating a new job

There are two types of jobs within Apogee Prepress

- Small repeat jobs, such as making proofs or preflighting incoming ads, are handled by so called hot tickets. After creating such a hot ticket, it continuously runs in the background. If you need a proof or need to get some pages preflighted or downsampled, just drop files in the predefined input folder or hotfolder. The system picks them up and does whatever needs to be done to them.

- For regular print jobs, you could define what needs to be done from scratch. It is however a much better idea to build a library of frequently used settings. You can usually pick up a job ticket from the library, change the job ID number, tweak the imposition template & output settings and have the job active in a few minutes.

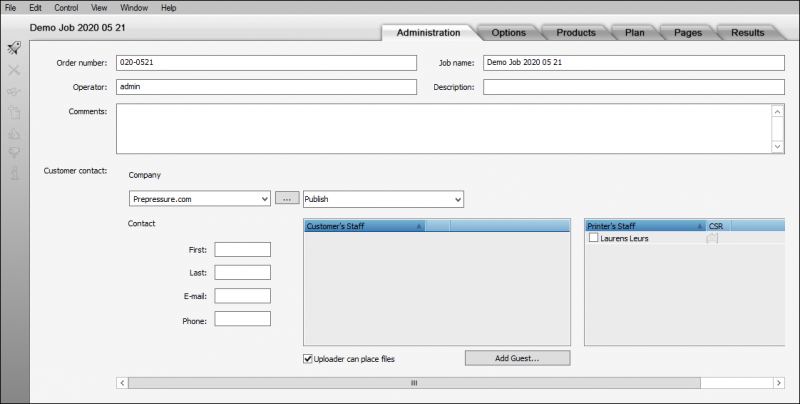

To set up a job, you first need to provide some administrative data, such as the order number and job name. You can also select the customer and allow them to upload content. In fully integrated setups, a management information system (MIS) can generate such a job automatically and populate all these fields.

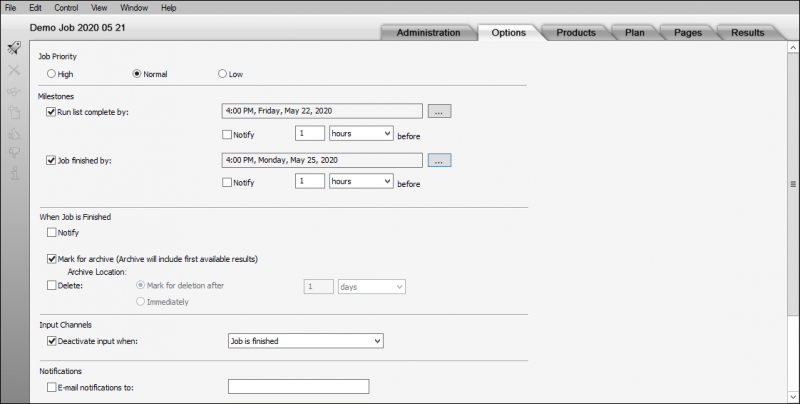

Jobs can have a priority level and deadlines for content intake and job completion. You can also specify that the job automatically gets archived once completed.

The production plan defines how the steps that the job data go though. The plan shown below is about as basic as it can get. The first icon in the row defines in which folder data need to be dropped. Then the data are checked and the pages are put in the right order in what is called the runlist. In the Impose step imposition takes place and then the flats are RIPped (or rendered, as Apogee calls it). Four sets of parameters define what the RIP/Renderer must do: trapping, color separation, color management and screening. The resulting data are then sent to the output device, typically a computer-to-plate or CtP devide. The last step in the process is the Press, used for defining settings like where the ink key data need to go.

Production plans can be far more sophisticated, with separate branches to define hardcopy proofing, online page approval or separate flows for mixed jobs, such as magazines for which the cover and inner pages are printed on different presses. Below is an example of a more sophisticated job setup which includes proofing and versioning (the job contains multiple language versions of all or part of the pages).

Managing production

Usually there are many jobs that are being worked on in parallel. You need to be able to keep track of things and make sure proofs and plates are ready in time. There are a number of ways a workflow can help in this.

- Warnings and alarms inform an operator when jobs are halted because of an issue, such as the corrupt file that fails to be processed or a platesetter running out of plates.

- Small icons indicate the status of each job, making it easy to get a quick overview.

- You can sort jobs on priority or target output device or the operator they are assigned to.

- For certain task processors such as the Renderer or the platesetter, you can manually change the order in which jobs or plates will be processed or output.

Thanks for the overview, I’m hoping you still plan to put up a few screen shots etc. Do you know how you can find out exactly what components of apogee you might have?