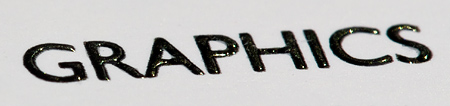

Thermography or thermographic printing is a printing process that causes text or graphics to be slightly raised from the substrate. The resulting visual effect is interesting, making this a technique that is commonly used on wedding invitations, letterheads, business cards, greetings cards, gift wrap, diplomas and packaging. Since it is also a tactile effect thermography can be used to print braille text. The above picture is a close-up of the text on a business card. To emphasize the raised lettering I placed a small light in the background.

The above picture is a close-up of the text on a business card. To emphasize the raised lettering I placed a small light in the background.

The thermographic printing process

Thermography combines a traditional printing method with a specific type of finishing. It can be done in a fairly manual fashion or using a completely automated system.

- Press sheets are printed using a regular offset press and a special type of ink that does not immediately dry.

- When working in a more manual fashion the printed sheets are then dipped into a powdered polymer or resin. This polymer sticks to the wet ink. The excess powder is removed by holding the sheets vertically and tapping their back. The same process can also be automated by having a machine dust the sheets with the colorless resinous powder. A vacuum system then removes the excess powder from the uninked areas.

- The sheets are then fed into a small oven that melts the polymer and fuses it to the ink. This takes just a few seconds. A cheaper but more manual option is to use a heat gun that blows hot air to achieve the same effect.

The powder that is used is available in a clear matt or high gloss finish which allows the ink color to show through. By printing text and graphics in two or more spot colors, this means that the artwork can contain multiple colors. The resin is also available in metallic gold and silver.

Designing for thermography

- Only one side of a substrate can be printed using thermography. You cannot have raised letters on both the front and back of business cards or invitations.

- Do not use type that is smaller than 6 points. The hole in characters like the ‘e’ will fill in.

- Avoid typefaces with very thin strokes.

- Try to avoid mixing large solid areas and small type on the same page. The printer can adapt the type of resin to the presence of either small text or large solids, but only one type of resin can be used.

- Avoid very large solid printed areas. Some shrinkage of the image is normal and this can cause distortion of the paper.

Other considerations

Keep in mind that thermography can be expensive. It isn’t only the resin and the process itself that add to the cost, trimming thermographed sheets can also be more expensive.

Be careful when using thermography for stationery that is used in a laser printer or photocopier. The fuser in the printer or copier can cause the resin to melt again and damage the device. Laserproof thermography or laser thermo is a process in which the polymer powder is cured by UV light. Such thermographic prints can withstand the temperatures found in laser printers and photocopiers without damaging the device.

hi,

we are trying to print some buisiness cards with thermosensitive ink that would react with the heat

can you do that?

thanks

Gee