The quality that today’s presses can deliver is often stunning. Printing is a mature industry and most printers have learned to achieve quality results while keeping costs under control. Sometimes, however, the printed result may not match your expectations. This page describes common printing issues, what causes them, and how they can be avoided. Keep in mind that printing is a physical process: some of the effects that are described are down to physical limitations. Much like the presence of gravity, there are natural effects that simply have to be taken as they are.

This list is split up into two main categories:

- Print artifacts – something is visible that should not be there.

- Print defects – something on the page(s) doesn’t look like it should.

Print artefacts

Hickeys (bullseyes)

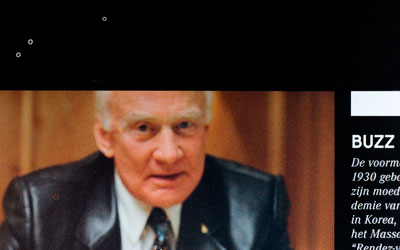

Hickeys are small non- or partially inked circles. The example below is taken from a magazine article. Notice the fourth hickey in Buzz Aldrin’s jacket.

Hickeys are caused by dirt, paper fibers, or hardened specks of ink on the printing plate or blanket. The problem is most visible in areas of heavy ink coverage. If a publication contains large solids, it can be difficult for printers to avoid an occasional hickey, especially on fast presses running large jobs.

Picking (plucking)

With plucking the paper’s surface is damaged, showing small bubbles or portions of its coating removed.

Picking is caused during ink transfer by the force of sticky ink. This is a quality issue but you should keep in mind that the choice of paper stock also plays a role.

Backside shines through

Sometimes the content of the opposite side of a page is visible, as shown in the theater guide below where two pictures of the back of the page shine through.

This effect is caused by a combination of a specific paper stock and fairly heavy ink coverage on the other side. Selecting a heavier paper stock helps. A designer can minimize this effect by properly aligning the content (text columns, image placement, folio, ..) of both sides of the page. Of course that advice doesn’t apply to things like advertisements that are not under the control of the designer.

Moiré

This refers to an unwanted pattern in pictures or tints. Moiré is a visual artifact that is created by the interference of two or more patterns that are superimposed on each other. There are different types of moiré:

- Object moire is a pattern that is visible in an image or artwork. The example below shows a picture taken in a museum. The pattern in the fabric behind the statue clashed with the CCD-pattern of my D70 digital camera, causing a weird color pattern to appear.

- Scanner moiré is a typical example of object moiré. It occurs when the optical system of a scanner interferes with a pattern in the original that gets scanned. This easily happens if you try to scan a printed original but it can also occur with pictures that have a repeating pattern in them such as a brick wall or textiles. Screening technologies can also cause moiré to appear, either because the pattern in a line screen interacts with a pattern on the page or because the patterns of the different colors (cyan, magenta, yellow, black,..) interfere with each other.

As a general rule, avoiding object moiré is the responsibility of the person creating the artwork, which might be the photographer or the scanner operators. Moiré caused by screening can be the responsibility of the printer as long as it is caused by interference between the colors themselves. If the screening interferes with patters in the supplies images, the printer could have avoided this unless

Offsetting (ink setoff) & ghosting

Faint replicas of printed images appear on other pages. Below you see two facing pages. The white paper at the bottom of the left page shows a darker region, caused by offsetting of the picture of Marilyn Monroe to the right. Marilyn’s picture actually shows a nice moiré-pattern which I left untouched on purpose.

These are two separate technical issues that lead to a comparable visual artifact. Offsetting happens if there is too much ink on the paper, the ink doesn’t contain enough driers or a job is sent through finishing while the ink is still too wet. Ghosting can be caused by press issues such as ink starvation or by a chemical reaction. The effect is similar to offsetting but it isn’t caused by ink transfer.

How to avoid offsetting: If the overload of ink is caused by incorrect color separations or the inappropriate use of registration color, the designer and the prepress department will have to fight it out. When offsetting happened because a job was rushed through finishing, it is the printer who should take responsibility or the one demanding an unreasonable deadline or the person who delivered the data too late. The printer can be held responsible for ghosting, but please take into consideration that ghosting effects can often only be discovered after the completed printing process has been completed.

Print defects

Bad registration

When all of the printing colors don’t align properly, that is referred to as a registration issue.

Flat tints look uneven

An example and description of this quality issue still need to be added.

The color on a spread shifts

An example and description of this quality issue still need to be added.

Images and tints are too dark or muddy

Sometimes images and artwork is too dark or the colors look muddy/

Muddy or uneven screens can occur as a result of dot gain. In some cases the prepress department could select a coarser screen, which of course has another, possibly unwanted, effect on print quality. Press operators can also minimize the effect by running the ink a little lighter.

Banding

There are two types of banding:

- Fine dark and light bands or streaks are visible. These bands run either vertically or horizontally.

- In graduated tints, such as an image of the sky with the color fading from a deep blue to a lighter tint, you see abrupt changes in the tint instead of a gradual color change.

Slurring

Slurring refers to a quality issue in which the edges of images or text are smearing. When slurring occurs in halftone images, it is called dot slurring.

Doubling

With doubling a faint duplicate of a printed impression is visible, slightly out of register with the solid image

In offset printing, this effect can be caused by a number of reasons, including paper deformations, static electricity or premature contact of the paper and the printing blanket before the actual impression is made. In die-stamping, bad registration causes it.

Your site is very informative. Myself I have a problem you could add to the quality issues page. I don’t know how is it called in english, so I show the following image:

[img]https://i.imgur.com/zdDLZz5.jpg[/img]

In portuguese it is called something like “véu”(veil) or “velatura”(veiling), because it causes a shadow over the plate covering the printing, even with a very wet plate.

This only happens when using a new blue ink can from a different brand. I noticed right away when opening the can it was more liquid then my other inks. It is a german ink(Epple), maybe it is only suited to low temperature countries like in central europe or there is a quality decrease to make it cheaper. I’ve been working almost 30 years in this and never had a problem with inks.

Hi I have a Harlan Coben paperback book and in the middle of the book there is a page which has been cut out with a zig zag edge. The page before it has the matching print and a large piece of black tape attached to it. I’m just intrigued as to how this would have happened as it could only have been when the book was printed.

Sorry if it’s not clear. I can send a photo of you wish. Its not a new book, I got it from a second hand store.

I would guess that this paperback, given the popularity of the author, was printed on a web press. These presses use large rolls of paper. When a new roll is loaded into the press, its beginning is attached to the end of the previous roll using tape. I guess the zig-zag edge and tape are from such a switch from one roll to another.

This article is very informative and very well written. Being in printing business i was even unaware of some of

these issues and had a hard time explaining my customers.

I would like to get your permission in posting this on our FAQ/Blog page with the credit being given to you.

Our FAQ is at http://support.printpapa.com/Main/Default.aspx

and the blog is at

http://blog.printpapa.com

Please let me know.

Thanks

Shawn