When several colors are printed on top of each other, there is a limit to the amount of ink or toner that can be put on paper. This maximum total dot percentage is referred to as either TIC (Total Ink Coverage) or TAC (Total Area Coverage).

When a designer ignores this technical limitation, the ink that gets laid down last won’t attach properly to the previous layers, leading to muddy browns in neutral areas. The ink also won’t dry properly on the press sheets. This can cause set-off where the ink of a still wet sheet rubs off on whatever is stacked on top of it.

Specifications for total ink coverage

Ink coverage is specified as a percentage: using 100% of each process color (cyan, magenta, yellow and black) equals 400% TIC. The actual maximum that is acceptable depends on a number of parameters:

- the printing process: digital, sheet offset, web offset (heatset or non-heatset), laser printer,…

- the paper stock (coated or uncoated,…)

- the speed at which the press runs

- how many colors are printed simultaneously (since intermediate drying time is important)

To know the TIC that the printer can handle, it is best to consult with them. The following percentages are industry averages:

- Sheetfed offset on coated paper (typical commercial printing jobs): 320 to 340%

- Heatset web offset (such as magazines): 300 to 320%

- SWOP: 300%

- Non-heatset web offset on uncoated paper (such as newspapers): 240 to 260% (In a 2011 analysis of thousands of advertisements that were sent to Dutch newspaper printers, 53% of all those ads had a TAC above 240%. The prepress systems at those sites fix this by ‘reseparating’ the files – which is not too difficult to do with today’s prepress systems but it is still a major hassle).

I haven’t found much information on inkjet devices or copiers but in general, these systems seem to be able to handle values between 300 and 350%.

How to avoid exceeding total area coverage

One error that is frequently made is to use the ‘registration’ color for design objects. Since registration equals 100% of each separation, the total ink coverage is always exceeded when this color is used. Never use ‘Registration’ for design elements.

Incorrect separations settings in Photoshop are also a possible reason why images are ‘too heavy’. The default color settings of Photoshop are optimized for web coated paper.

Another easy way to cause TIC-related issues is the inappropriate use of overprint.

How to check total ink coverage

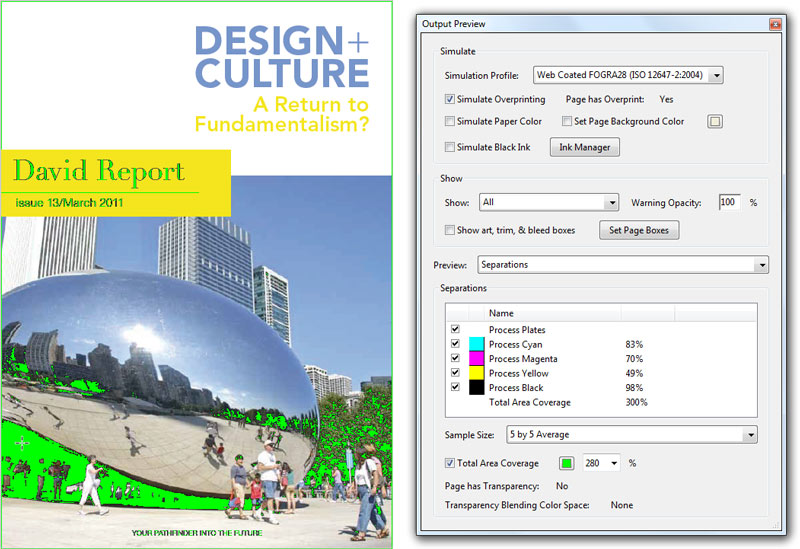

Adobe Acrobat Professional has a Total Area Coverage setting in the Output Preview settings. This can be found in the Print Production tools. You specify a threshold value and any area within the PDF that exceeds this value is highlighted. The screen capture below shows page areas highlighted in green wherever total area coverage exceeds 280%. The cursor is positioned in the lower-left corner of the statue with Acrobat showing the ink coverage for that spot.

Similar functions are offered by several prepress systems, which can check complete press sheets for any TIC-related issues.

Adobe InDesign has a Total Ink Coverage indicator in the Separations Preview window.

There are preflight tools like Enfocus Pitstop that can check total ink coverage. Keep in mind that some of these applications only check vector objects and don’t check within images or take overprints into consideration.

More information

To discuss TIC, check this thread on the B4print forums.

Hello, I am a prepress-studiomanager and today I had an rare thing to deal with. We have to print a magazine in offset and the designer had used several gradients in cmyk (on multiply setting) on top of a photo placed in Indesign. The photo was placed in RGB. The pdf output was correct and the document was alright, except the item with the gradiënts on top. This page (only page in the document) is not effected with the PSO uncoated profile and shows an inkcoverage of 340%. Which should be max 300%.

The only way to solve this problem is to export straight to profile without “preserve numbers”. Though this is not recommended because it effects the black text not being only black but an built-up version.

Has anyone an idea what the real problem is? Or is it an bug in indesign of something…?

There is a process for separations that does “Under color removal”. It reduces the amount of ink used so that it limits the amount of TIC or TAC. It works well. The printed product looks cleaner and crisper.

UCR (the abbreviation of Under Color Removal) does indeed reduce the amount of ink used to print grayish colors. There is a second technique called Gray Component Replacement (GCR) that replaces equal portions of cyan, magenta and yellow by black in all colors. It can lead to even bigger ink savings.

Also there is APFill Ink Coverage Calculator software. It calculates the total ink coverage (TIC) for all of the pages in a PS file or a PDF file. Coverage results are separated for each CMYK spots + Pantones.

http://avpsoft.com/products/apfill/

Hi,

@Roo, @Arron: Thanks for the comments!

We are proud to announce tha we have updated Printcalc to support EPS and PS files in addition to PDF files.

Mark Redman

Hi,

We have just launched our PrintCALC product as a free service. PrintCALC reports on the CMYK Coverage of a PDF file.

Its available here: http://printcalc.net/

Hope this helps.

Mark Redman

Made4Print Limited

Hi Mark,

Your PrintCALC utility is great – thank you!

Roo

PitStop Pro most certainly checks ink density in images. You can specify the area of calculation for averaging.

FlightCheck Pro can report the ink density but it streams each individual pixel with no ability to average.

But in order to truely calculate the ink density and take into consideration stacking order and over prints you have to have a RIP to perform that function.

You’re right Matt, thanks for the correction. I overlooked the fact that PitStop 7 can indeed check ink densities in images. I have updated the page content.

Just to be on the safe side, I doublechecked if this release can preflight ink densities in overprints but that still isn’t true. Funnily enough both InDesign and Acrobat 8 Professional warn about a 100% black text in overprint on 100% CMY but PitStop cannot check this. I remember a discussion in the Ghent PDF Workgroup about this in which the required CPU overhead was cited as the main restriction for not doing this type of check.